Smart Factory

Smart Manufacturing and Responsible Production

Inventec recognizes that establishing cost-efficient, optimized manufacturing processes and enhancing the digital skills of employees are crucial steps for companies to address global supply chain risk issues. Inventec’s digital transformation path focuses on operating items such as yield rates, utilization rates, and quality. In addition to end-to-end production and digital supply chain establishment, Inventec also collaborates with domestic and foreign partners to develop forward-looking technologies and services combing 5G, AIoT and Cloud. Inventec teams up with these partners to deliver 5G manufacturing Intelligence solutions for ecosystem manufacturers in order to improve OEE production efficiency and implement the concept of ESG responsible production.

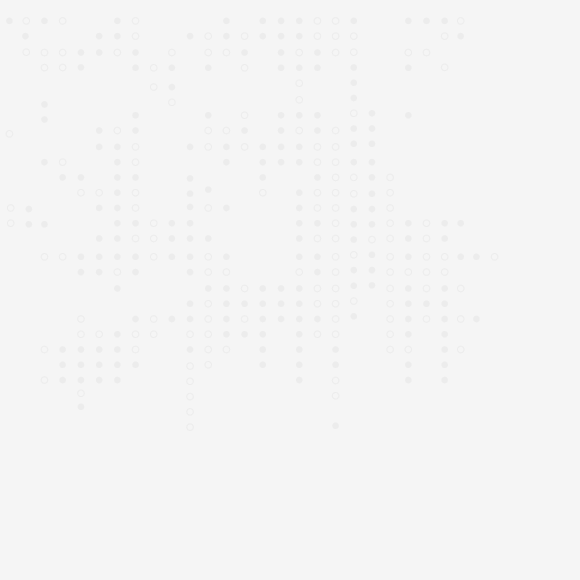

Digital Transformation Blueprint for 5G Smart Factory

Inventec's 5G manufacturing intelligence integrates the "Man-Machine-Material-Method-Environment" on the factory side and the "Production and Operation Management-Marketing Management-Human Resource Management-R&D Management-Finance Management" on the enterprise side, and further extends to ecosystem manufacturers, catering to a real-time, high-efficiency management approach for the globalized production model.

Inventec 5G Manufacturing Intelligence Solution

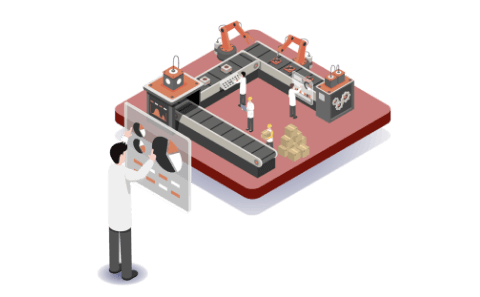

AI-Optimized Production Management Platform

- Hardware Integration: robots, edge computing, computer vision, sensing systems

- Artificial Intelligence: analysis, optimization, control, performance enhancement

Data Scientist Development

- Target: production line operators, technicians, and engineers

- Learning: use of digital tools and responsible for the management of diverse digital production lines

Inventec 5G Manufacturing Intelligence Solution

Inventec has successfully transformed the manufacturing industry into a "intelligent manufacturing industry" by integrating IT manufacturing systems, CT heterogeneous networks, and OT production line applications with 5G private network technology and AI intelligent analysis.

Digital transformation case

5G O-RAN Smart Factory

Through 5G and AI, Inventec collaborates with leading manufacturers in the smart production space within the digital transformation business ecosystem to envision innovation for the future, creating a new generation of 5G smart factories with efficient production technology and services.

Combined with AI to reduce misjudgment rate, AI-AOI simplifies manual re-inspection and enhances the first pass yield rate.

Integration of 5G and heterogeneous network sensing technology such as BLE to collect information about the environment (e.g. temperature and humidity), vibration, production barcodes, etc., along with large-scale machine data collection and real-time alert mechanisms, is able to achieve maintenance prediction for critical production machinery, machine management, and production history tracking, ultimately improving utilization rates.

Developing multiple sets of AI-based Digital Twins to comprehensively monitor the issues of production line personnel, including the operating time, motion checks, SOP procedures, and even workplace safety, and conducting analysis and optimization to improve production efficiency.

- Note: Total Cost Ownership