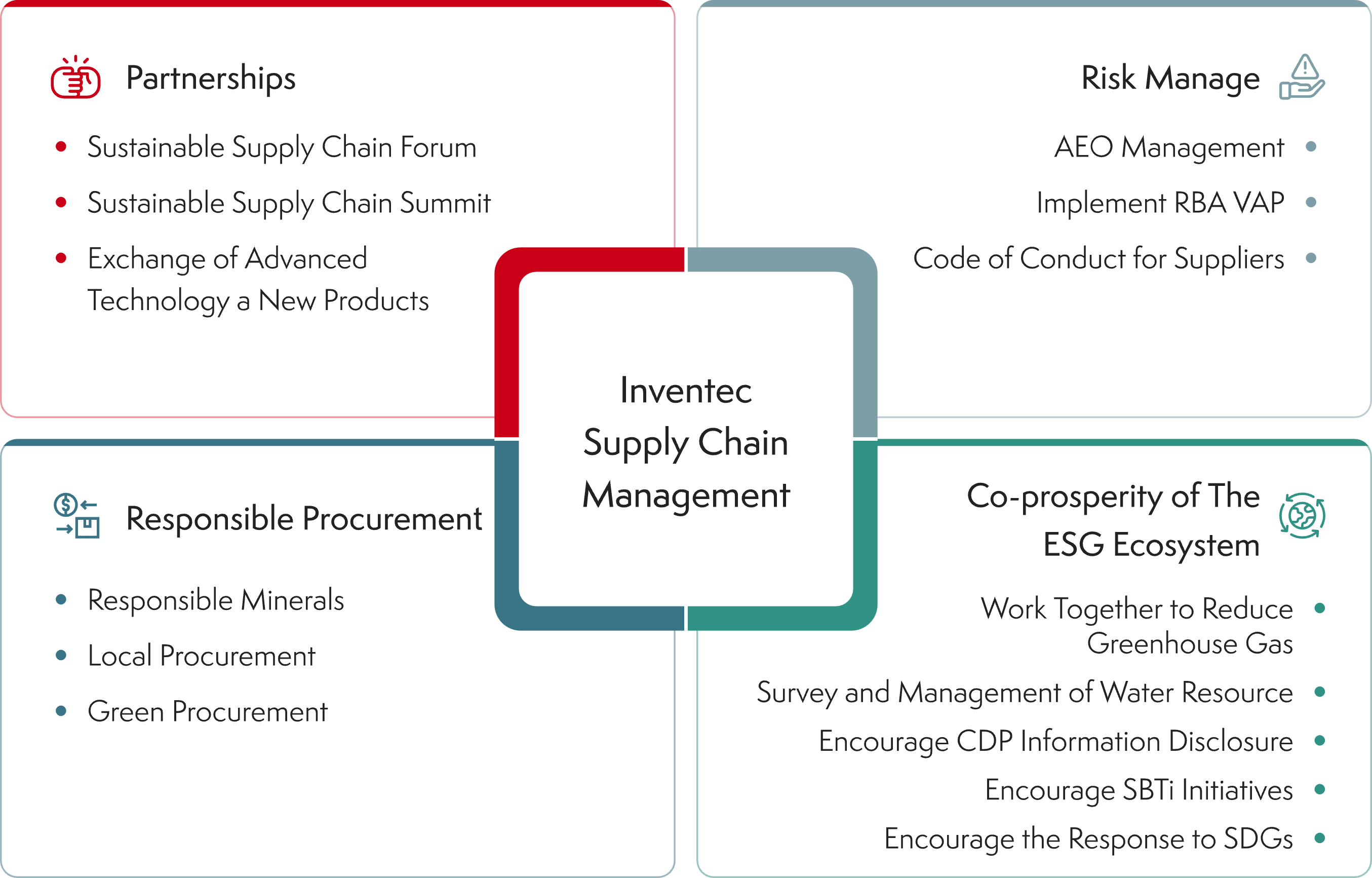

Sustainable Supply Chain Management

Sustainable Supply Chain Management

In 2024, Inventec transacted with 1,058 suppliers. To identify sustainability risks, Inventec investigates and screens suppliers across three dimensions: governance, social, and environmental. Based on industry characteristics, procurement models, geographical relationships, and other factors, Inventec has established a supplier risk identification process. This process involves classifying all suppliers by risk level. Inventec uses the RBA Code of Conduct Compliance Statement and the Inventec Supplier Code of Conduct as the basis for supply chain management. These frameworks guide Inventec's close collaboration and engagement with suppliers to seek mutually beneficial development and a win-win situation for sustainability.

Supplier Classification | Definition (Electonic components, mechanical components, modular materials) | 2024 |

|---|---|---|

| Tier 1 Critical Suppliers | Suppliers engaged in direct transactions with annual transaction amount exceeding US$40,000 | 862 Suppliers |

| Tier 1 Significant Suppliers | Strategic suppliers with direct transactions, industry benchmarks, high-volume vendors selected as critical suppliers that are commercially important to Inventec, or high-risk suppliers requiring attention (i.e., those with significant actual or potential risks) | 92 Suppliers |

| The ratio of transaction volume of Tier 1 Significant Suppliers to that of Tier 1 Critical Suppliers | The percentage of transaction amount | 82.10% |

| Non-Tier 1 Suppliers | Suppliers that transact through agents | 162 Suppliers |

| Non-Tier 1 Significant Suppliers | Suppliers selected from industry benchmark suppliers trading through agents or from large-volume vendors. These suppliers are identified as either key suppliers of commercial importance to Inventec or high-risk suppliers requiring attention (i.e., suppliers with significant actual or potential risks). | 5 Suppliers |

| Number of Tier 1 Critical Suppliers audited | 43 Suppliers | |

2024 Supplier Compliance Document Signing Rate

Item | Existing Suppliers | New Suppliers |

|---|---|---|

| Inventec Environmental Commitment Letter | 99.7% | 98.7% |

| RBA Code of Conduct Compliance Statement | 99.7% | 100% |

- Note: Excluding customer-designated suppliers.

Supply Chain Risk Management

Based on a comprehensive assessment of supplier management risks and material risks, Inventec shortlists suppliers for annual audits and conducts these audits in accordance with the internal control procedures specific to each site. Following the audits, Inventec actively tracks and guides suppliers to complete necessary corrections or makes decisions to replace them if required. In 2024, based on the definition of critical components, materials were categorized into single-source suppliers and high-pollution manufacturing materials to identify high-risk materials. A total of 116 suppliers with significant actual or potential negative impacts were evaluated. The audits identified 186 findings in total. Corrective action plans for all identified issues were developed and tracked to completion within two weeks. The audit implementation achieved a 100% completion rate and 100% of the suppliers have been fully tracked and have completed the necessary improvements.

The audit findings of existing suppliers in 2024

- BCP - Business continuity plan

- RBA - Responsible Business Alliance

- HSF - Hazardous substance free

Third-party Assessment for Suppliers

To meet the supply chain management requirements of RBA, supplier auditors of the factory floor conduct supplier on-site audits based on the latest version of supplier audit criteria covering labor, health & safety, environment, ethics and management systems. In 2024, Inventec worked with 1,058 suppliers, of which 31 were identified as high-risk. Among these, 20 suppliers were notified to undergo the RBA VAP (Validated Assessment Program) audit. As of 2024 year-end, 14 suppliers had completed the audit. To further mitigate supply chain risks, Inventec will continue to implement VAP audits, fulfilling its commitment to sustainable supply chain practices.

New Supplier Consultation Management

Inventec has established a dedicated "Sustainable Supply Chain Consultation Team", a cross-functional team composed of experts from R&D, procurement, component engineering, and supplier quality management departments. This task force is responsible for conducting comprehensive assessments and providing guidance to new suppliers. The new supplier evaluation is based on the following criteria:

- Quality System Implementation and Management

- HSF (Hazardous Substance Free)

- Technical Capability Development and Evaluation

- Supplier Fundamental Capabilities

- Procurement Operations Management

- Business Continuity Plan

- Counterfeit Component Control

- Supplier Corporate Social Responsibility

Responsible Procurement

As a member of RBA and RMI, Inventec is committed to promoting and complying with relevant standards, and publicly announcing Inventec Responsible Minerals Sourcing Statement. Inventec has conducted investigations with the Conflict Minerals Reporting Template (CMRT) since 2011, and during the period Inventec has gradually introduced the automated system and completed the automation of metal refinery compliance verification. In 2024, in accordance with RMI requirements, Inventec adopted the latest versions of both the CMRT and the Extended Minerals Reporting Template (EMRT) to conduct supplier surveys. Suppliers are required to perform reasonable due diligence on their supply chains to ensure that materials provided to Inventec do not contain conflict minerals sourced from conflict-affected regions and countries. Additionally, Inventec is evaluating the implementation of the Additional Minerals Reporting Template (AMRT) to meet evolving customer expectations and regulatory requirements.

Inventec's Responsible Minerals Goals

Compliance with RMI’s latest CMRT and EMRT and the other mineral investigation requirements from the customers

Affirmation from the customers’ annual supplier evaluations and experience sharing with customers to obtain customers’ satisfaction

Continuously optimize investigation system and use automated comparisons to save man-hours and ensure metal refineries’ compliance

Annual Sustainable Supply Chain Forum and 100% compliance with the RMI metal refinery list

Item | 2024 Result | 2025 Goal |

|---|---|---|

| Responsible minerals investigation reports conducted for the suppliers in compliance with RMI Smelter & Refiners Lists | 100% compliant for Inventec’s own suppliers | 100% compliant for Inventec’s own suppliers |

Sustainable Supply Chain Engagement

Suppliers are crucial partners for Inventec. To encourage their support in Inventec's initiatives related to quality, cost, delivery, technical capabilities, services, and RBA compliance, we have been inviting senior executives of strategic suppliers to participate in the sustainable supply chain exchange meeting every year. In 2024, the Company hosted 5 sessions of on-site “Sustainable Supply Chain ESG Seminar” inviting suppliers to share experiences and best practices. Furthermore, the Group also organized 2 Sustainable Supply Chain ESG Workshops for suppliers, 2 sustainability forums focused on sustainable supply chain topics, and internal procurement training sessions to foster robust and close partnership.

Sustainable Supply Chain ESG Workshops

In 2024, a total of two ESG sustainability supply chain workshops were held for suppliers. The second event, titled "Sustainable Supply Chain Partner Day," was held on December 13, 2024, at the Jiantan Youth Activity Center, with 137 representatives from 129 supplier companies in attendance. The workshop covered topics including the Responsible Business Alliance (RBA), occupational health and safety, information security, greenhouse gas inventory, and the reduction of hazardous substances. Supplier scores are consolidated from various international rating platforms to develop a comprehensive supply chain dashboard. Benchmark companies in each industry are then selected, and ESG case studies across different dimensions are shared during the Supply Chain ESG Workshop. This initiative encourages supplier partners to actively participate in international ratings, offers benchmarking opportunities against industry peers and global leaders, and enhances the overall competitiveness of the value chain.

Sustainable Supply Chain ESG Seminars

In 2024, Inventec hosted five ESG Seminars for suppliers, fostering experience-sharing and engagement. The seminars focused on sustainability, including green platform development, supplier management aligned with ISO 14064 and ISO 14067, sharing practices on water resource reuse, and planning and approaches for procuring green electricity.

Advanced Technology and New Product Exchange

Since 2009, Inventec has invited suppliers to participate in the Advanced Technology and New Product Exchange Forums. This initiative aims to promote a deeper understanding of advancements in technology, new product developments, and evolving global ESG trends. In 2024, a total of 302 sessions were held.

Building Supplier GHG Inventory Capability

Inventec began developing the iSupplier GHG Management Platform in 2021 and simultaneously launched supplier GHG emissions surveys. In 2024, Inventec further optimized the iSupplier platform and continued to drive supplier participation in GHG emissions surveys. These surveys covered 649 suppliers from the Personal Solution Group and the Enterprise Business group. In addition to offering suppliers courses and guidance on greenhouse gas inventory, Inventec also actively encourages suppliers to pursue third-party verification as a critical step in their decarbonization journey. The Company progressively guides them to establish carbon reduction targets, and encourages them to join the Science Based Targets initiative (SBTi), with the ultimate goal of achieving net-zero carbon emissions by 2050.