Safe and Healthy Workplace

Occupational Health and Safety Management System

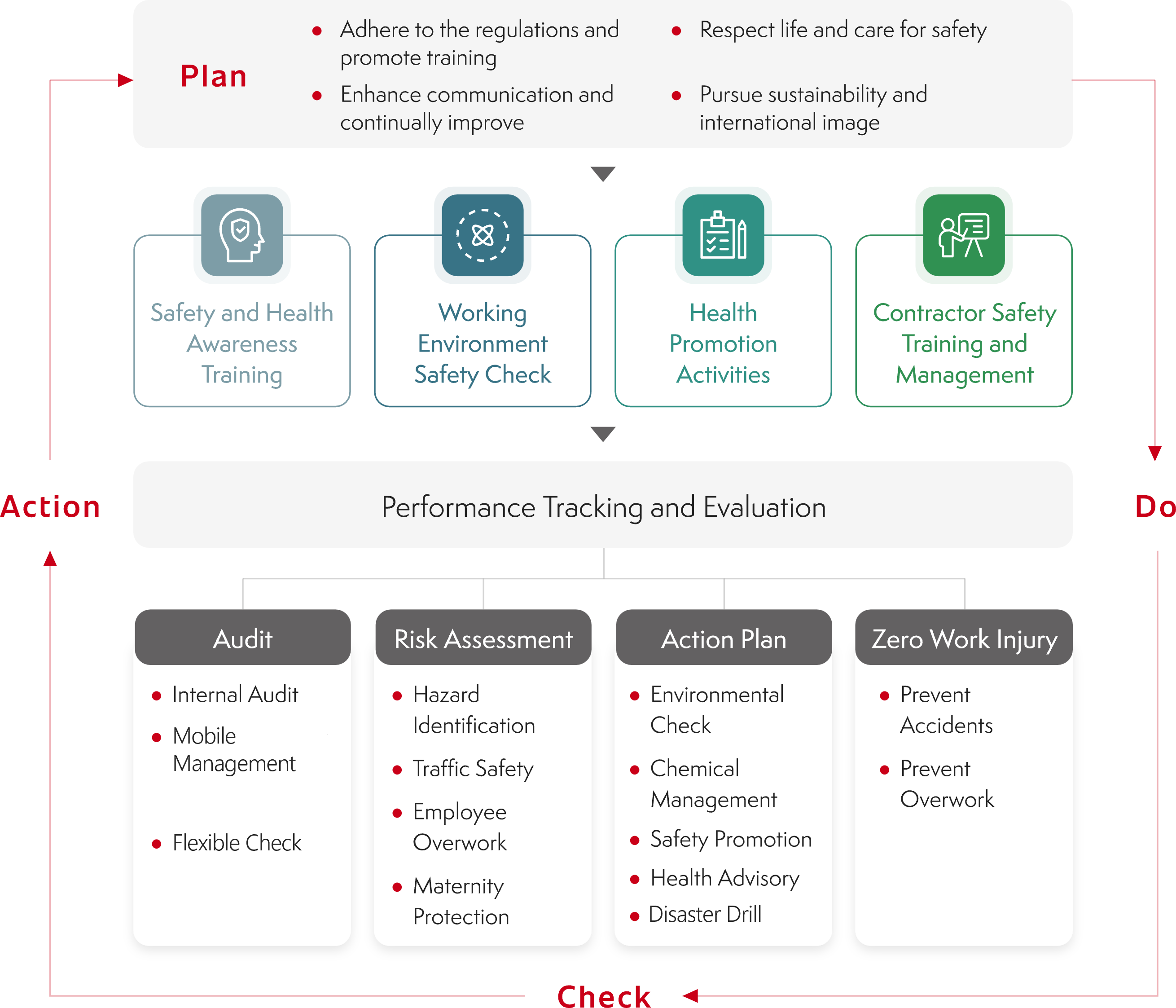

To comprehensively implement safety and health management, Inventec has adopted an Occupational Safety and Health Management System. All thirteen global factories have been certified through the International Occupational Safety and Health Management System (ISO 45001). Furthermore, our corporate headquarters has received certification through the Taiwan Occupational Safety and Health Management System (CNS 45001). In terms of execution, Inventec follows the four steps of the PDCA (Plan, Do, Check, Action) cycle to carry out various safety and health measures, preventing occupational accidents and illnesses and ensuring a stable, safe, and healthy working environment for all workers, both employees and non-employees.

Occupational Safety and Health Committee

Each Inventec plant has established an Occupational Safety and Health Committee (hereafter referred to as the OSH Committee), which convenes quarterly to jointly deliberate on various occupational safety and health issues. The proportion of labor representatives exceeds the one-third requirement stipulated by law. The primary responsibilities are as follows:

- Provide recommendations on the occupational safety and health policy formulated by the employer.

- Coordinate and propose the occupational safety and health management plan.

- Review the implementation plan for safety and health education and training.

- Review the operating environment monitoring plan, monitoring results, and adopted measures.

- Review health management initiatives, occupational disease prevention, and health promotion eff orts.

- Review various safety and health proposals.

- Review business unit's self-inspection and safety and health audit matters.

- Review preventive measures for hazards associated with machinery, equipment, raw materials, and substances.

- Review occupational incident investigation reports.

- Evaluate on-site safety and health management performance.

- Review safety and health management matters related to contractors.

- Address other matters related to occupational safety and health management.

Occupational Safety Measures

To effectively implement occupational safety and health management, Inventec has established internal control documentation based on the ISO 45001 system, ensuring that safety and health-related procedures are enforced. Inventec regularly monitor the daily safety and health performance at each plant site, aiming to achieve the objectives of seven key areas outlined in the Occupational Safety and Health Policy.

- Legal Compliance

- Employee Engagement

- Enhanced Communication

- Risk Management

- Continuous Improvement

- Zero Hazard

- Value Chain Collaboration

Contractor Identification Mechanism

Inventec mandates that all contracted projects appoint legally required safety and health management personnel. Furthermore, contractors must ensure their workers are covered by labor insurance. Relevant qualifications and documentation must be presented before contractors are allowed to enter the facility and commence operations. Prior to the start of any construction, contractors are required to provide a project-specific risk assessment along with corresponding mitigation measures. Daily environment, safety, and health audits are performed throughout the duration of construction, and any identified deficiencies must be rectified immediately. For regularly engaged contractors, Inventec conducts annual performance evaluations focused on their safety and health records. These evaluations serve as a critical reference for construction project-initiating departments in their contractor selection process.

To effectively prevent fire incidents, Inventec has established an Industrial Safety Strategic Alliance. This initiative aims to enhance the Group's safety management performance by investigating the root causes of any incidents through systematic audits and follow-up actions. The audit scope includes high-risk plant sites and new construction projects across the Group. Tailored audit plans are formulated based on the specific risk characteristics of each site to ensure the rigorous implementation of all safety measures. As a result of these efforts, the Group recorded zero fire incidents in 2024.

.jpg)