Quality Management

Product Quality Management

In the face of changes in the industry environment, Inventec realizes that “innovation and quality” are the two most important success factors in business operation. Therefore, we remain dedicated to our core business and take “innovation” as the cornerstone of industry differentiation, actively seeking a major breakthrough in the competitive landscape and striving to maximize “quality” in order to fulfill our commitments to customers and partners, and meet the demands in the market.

Inventec believes that “product quality” is composed of five key elements

- Standard operations of quality management system

- R&D quality

- Material management quality

- Production process quality

- Employee expertise and quality, including environmental management

Inventec Quality Policy

Comply with applicable

laws and regulations

Set high quality

objectives

Create customers’

new needs

Quality Goals

Since 2012, Inventec has launched a company-wide improvement and innovation initiative. Utilizing systematic, standardized logical analysis, this initiative drives improvement and innovation related to production issues and establishes a unified language for improvement and innovation across the Company: IRP (Inventec Rationalization Proposal), PIP (Personal Improving Proposal), QIT (Quality Improvement Team), and QI (Quality Improvement Proposal Count). These efforts reflect Inventec’s core values of "Innovation, Quality, Open Mind, Execution and Accountability."

| Item | 2021 | 2022 | 2023 | 2024 |

|---|---|---|---|---|

| Number of continuous improvement cases (QIT) | 433 | 439 | 452 | 497 |

| Number of closed cases for IRP & PIP | 9500 | 11520 | 11520 | 1835 |

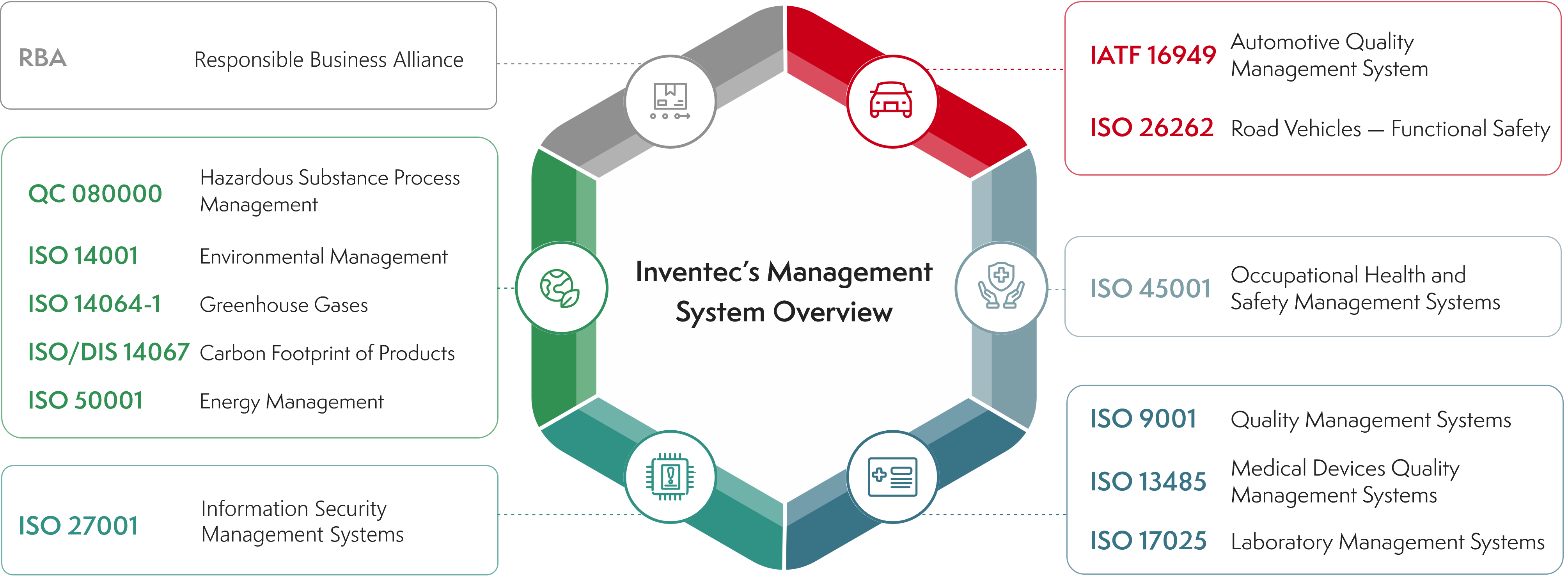

Quality System Certification

In order to maintain the corporate improvement mechanism and pursue the best product quality, Inventec has obtained a number of management system certifications that meet international standards.

Enhancing the Quality Competency of All Employees

To continuously cultivate problem-solving skills among all Inventec employees, we have been strengthening the company’s quality capability and enhancing overall industry competitiveness through the diversity approaches.

- Promoting proposals and quality improvement team programs.

- For employees and supplier partners, Inventec regularly conducts quality training programs, including e-learning, seminars, and corporate visits.

- Development of in-house quality instructors to pass on their experience.

Training for In-house Instructors

- Professional training program for instructors

- Project instructor certification system

Quality Competition Events

- Annual improvement project competition

- QCC (Quality Control Circle) results announcement